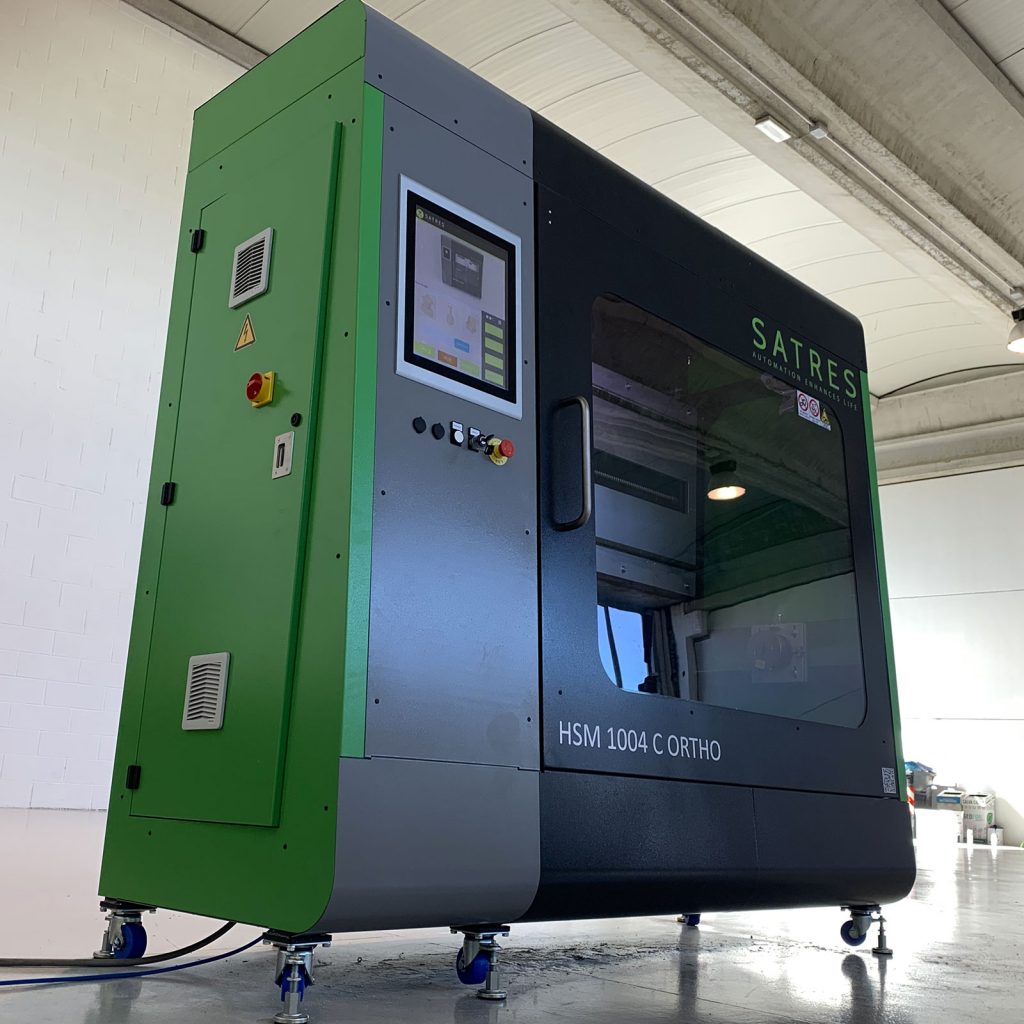

Satres offers a simple, flexible and economic solution to the orthopedic market. We are speaking about the HSM 1004 C ORTHO.

Why did Satres decide to enter into the O&P world?

Fabio Diana, Satres’s CEO, explains this in the following interview.

“We knew the orthopedic market in detail because one of our partner is an expert in this field. We had several meetings with him to figure out what were the main aspects that would help the professionals of the Orthopedic Sector to grow considerably their competitiveness. We did a market research and we found out where the competitors are. Then we discussed with the final buyers and we understood their needs. Something was missing in the Orthopedic field. Over the years, indeed, many Orthopedic labs have given up to innovation because of two reasons: the first one is the technical complexity of using CNC machines; the second one is the prohibitive purchase cost of these machines. We are talking about a sector that in Italy is already strongly penalized compared to the rest of Europe because the prices for supplies at national health facilities have been blocked for many years, contrary to what is happening for the cost of labor and cost of living in general. From here we decided to develop a new “All in one” product that had the following key features: ease of use, top-level performance, great flexibility and at the same time an incredible value for money. We love our customers and we are proud to have created this machine for them.”

Aren’t you afraid of the most important competitors?

“The comparison with competitors already established on the market such as Rodin 4D, Vorum, BZT GmbH, Mecanumeric, Nuova Ginev srl, Biosculptor and suppliers of multi-axis robots such as Roboticom is stimulating for us. We like new challenges and we think we can help the companies that have not approached the O&P processing sector yet for fear of the difficulty of introducing a numerical control machine into the company and also the companies that have already purchased a system but they want to renew it with a latest generation machine. ”

“The comparison with competitors already established on the market such as Rodin 4D, Vorum, BZT GmbH, Mecanumeric, Nuova Ginev srl, Biosculptor and suppliers of multi-axis robots such as Roboticom is stimulating for us. We like new challenges and we think we can help the companies that have not approached the O&P processing sector yet for fear of the difficulty of introducing a numerical control machine into the company and also the companies that have already purchased a system but they want to renew it with a latest generation machine. ”

What CAD CAM systems do you recommend to your customers?

“With the HSM 1004 C ORTHO we offer its proprietary OrthoCAM4X CAM software, which is optional and can be integrated into the HSM C ORTHO Line, with which it is possible to program processes quickly and intuitively, without any knowledge of CAM programming.

HSM 1004 C ORTHO can be compatible with any CAD software. For importing scanned shapes and modeling 3D shapes we recommend Pi.cas.so – provided by Orthoiberica.”

How is the HSM 1004 C ORTHO different from other milling systems?

“It is a real numerically controlled machine with superior performance, it is very easy to use and it has a unique flexibility. With this machine, an orthopedic laboratory can cover a good part of the processing needs and can make customized busts, corsets, leg, feet, orthoses, seats, abutments, supralleolar and insoles. Such simplicity and flexibility can be translated into a very fast return on investment for the end customer. ”

Would you like to have more information about the 4 Axis milling machine? Contact us: Click here