The Professional 3D Printer for Orthopedic Laboratories

Advanced FDM Technology for Custom Orthopedics

The Fused Deposition Modeling (FDM) technology is the beating heart of HELIOS Ortho. This cutting-edge process enables the creation of custom orthoses with extreme precision and quality. FDM printing is an additive manufacturing method that deposits melted thermoplastic materials, layer by layer, to create 3D objects. With HELIOS Ortho, this technology has been optimized to meet the specific needs of orthopedics, ensuring exceptional quality.

Unrivaled Performance

HELIOS Ortho offers unparalleled performance in the field of 3D orthopedic printing. Its printing precision of up to 50 microns ensures that every detail is rendered with extreme fidelity. Additionally, its large working area of 600x600x600 mm allows for the production of orthoses of any size with a single 3D printer, making the process more efficient and cost-effective.

Advanced Materials for Exceptional Results

The versatility of HELIOS Ortho is evident in its ability to work with a wide range of materials, including super-polymers and technical thermoplastics such as PEEK and Carbon PEEK. These materials offer superior performance compared to traditional materials, ensuring greater durability and optimal comfort for the patient.

Total Control and Automation

HELIOS Ortho offers maximum control through its remote control functionality. You can manage the 3D printer from anywhere via PC or smartphone, enhancing your flexibility and productivity. Additionally, the 3D printer is equipped with a heated chamber up to 100°C, ensuring perfect material adhesion during printing.

Additional Technologies for a Safe Working Environment

To ensure a safe and clean working environment, HELIOS Ortho is equipped with a filament drying system and an air purifier with HEPA filter called ‘CleanAIR.’ These devices help keep the 3D printer’s workspace free from impurities, which is crucial when working with advanced materials.

Material Freedom and Cost Savings

With HELIOS Ortho, you’re free to use any type of material, without the need to purchase expensive printing materials directly from the manufacturer. This flexibility allows you to reduce operating costs and fully leverage your creativity in orthopedic design.

Welcome to Helios Ortho: The Revolution in Custom Orthopedics

HELIOS Ortho is the future of orthopedic production. It combines innovative FDM (Fused Deposition Modeling) technology with 3D printing to enable the creation of custom orthoses with unparalleled performance.

Redefine Orthopedic Production with HELIOS Ortho

In summary, HELIOS Ortho is the key to high-quality custom orthopedic production. With exceptional performance, material versatility, and total control, the HELIOS Ortho 3D printer is redefining the industry. Whether you’re working on AFOs, helmets, forearm braces, seating shells, or insoles, HELIOS Ortho makes the process simple, professional, and highly efficient.

The 3D Revolution in Orthopedics is Here

HELIOS Ortho is the future of custom orthopedics. With exceptional printing performance, wide versatility, and total control, we are redefining orthopedic production. Choose HELIOS Ortho for cutting-edge 3D printing solution that will enhance patient comfort and streamline your work in orthopedics.

Contact us and Discover more about how HELIOS Ortho is changing the game in custom orthopedic production.

Revolutionize Orthopedics: HELIOS Ortho Redefines the Industry. Discover how HELIOS Ortho is changing the landscape of custom orthopedics.

Custom Precision: Every Detail Matters

HELIOS Ortho offers precision up to 50 microns to ensure flawless custom orthoses.

Improve Patients' Lives: Superior Quality Orthoses

Thanks to advanced materials and exceptional performance, HELIOS Ortho enhances the comfort and quality of life of patients.

Impeccable Efficiency: Large Sizes, Single Print

With a working area of 600x600x600 mm, HELIOS Ortho allows you to produce orthoses of any size with a single print, enhancing efficiency and saving valuable time.

Remote Control: Limitless Flexibility

Manage the printer from anywhere via PC or smartphone, ensuring total control over orthopedic production.

Materials of Excellence: Unmatched Durability and Comfort

Work with state-of-the-art super-polymers and advanced thermoplastics for exceptional results.

Ambiente di Lavoro Sicuro: Lavora con Serenità

HELIOS Ortho is equipped with drying and air purification technologies for a clean and safe working environment.

Material Freedom: Unlimited Creativity

Use any type of material without constraints, saving significantly on operational costs.

Revolutionary Applications for HELIOS Ortho

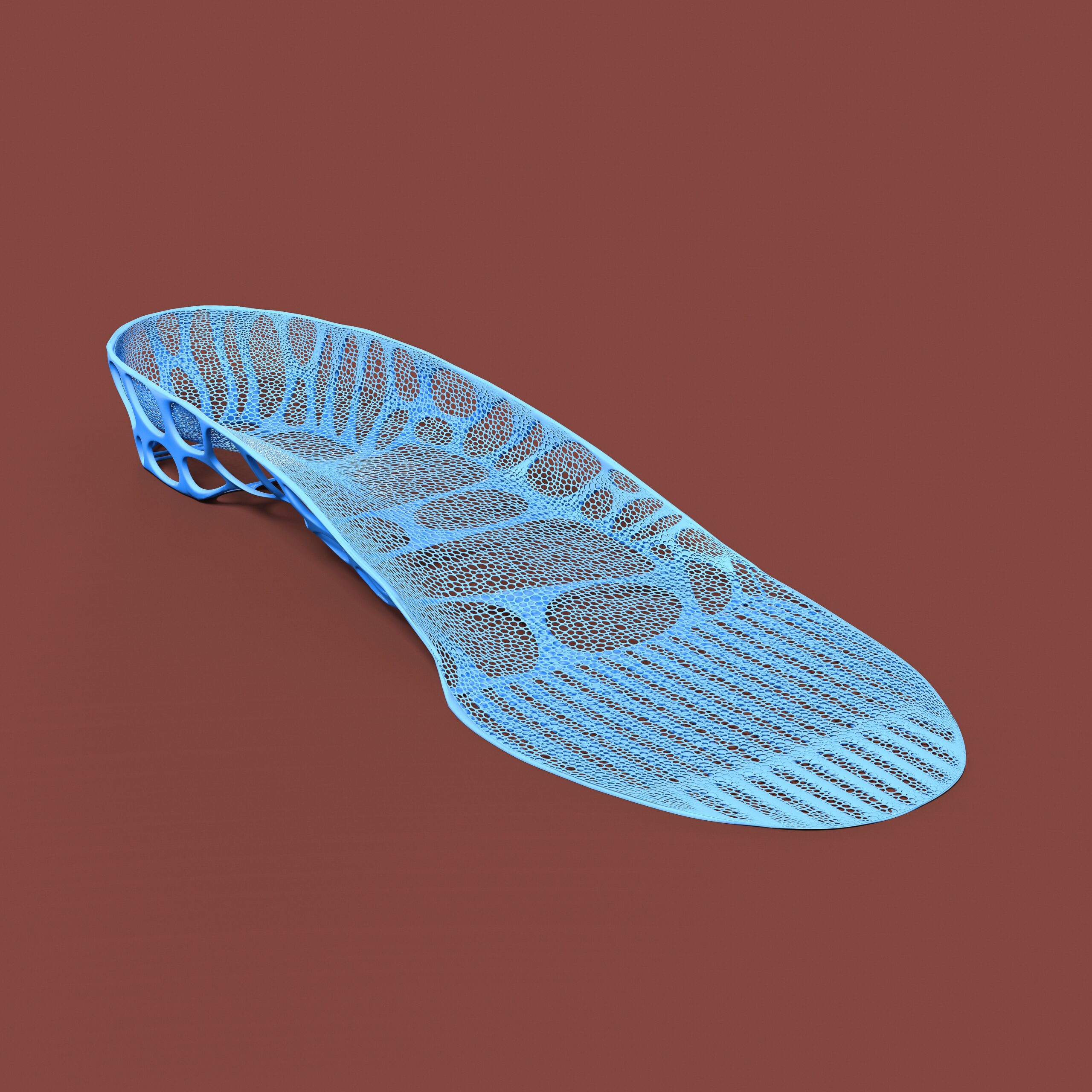

HELIOS Ortho allows for the printing of custom orthoses with technical and structural materials.

HELIOS Ortho is not just a 3D printer, but an open door to infinite possibilities in the field of personalized orthopedics. Its innovative applications are transforming the way custom orthopedic devices are designed and made.

1. Custom AFOs: Thanks to the extraordinary precision and quality of HELIOS Ortho, it is possible to create custom AFOs (Ankle-Foot Orthoses) that offer superior support and unmatched comfort for patients.

2. Orthopedic Helmets: Orthopedic helmets require a perfect fit to ensure optimal protection. With HELIOS Ortho, it is possible to create custom helmets that fit perfectly to the patient’s shape.

3. Forearm Braces: The printer’s precision ensures that forearm braces are made with the utmost attention to detail, providing the necessary support for recovery.

4. Busts: HELIOS Ortho can be used to create custom busts, ensuring maximum comfort and necessary support.

5. Custom Insoles: Custom orthopedic insoles are essential for those suffering from foot problems. With HELIOS Ortho, it is possible to produce insoles that perfectly fit the structure of the patient’s foot.

6. Innovative Prostheses: HELIOS Ortho can be used to create advanced custom biomedical prostheses. This opens up new possibilities for improving the lives of people with disabilities.

7. Variable Density Seats: HELIOS Ortho can be used to create variable density seats. This opens up new possibilities for improving the comfort and lives of people with disabilities.

A World of Opportunity

The applications of HELIOS Ortho are only limited by your imagination. Thanks to its versatility, you can create a wide range of personalized orthopedic devices that improve patients’ lives. Discover how HELIOS Ortho is redefining the orthopedic sector and join the revolution.

| Technical data | |

| Dimensions of the 3d printer | X = 1000 mm Y = 1200 mm Z = 1700 mm |

| Print volume | X = 600 mm Z = 600 mm Y = 600 mm |

| Precision | 50μm |

| System weight | 280 Kg |

| Printable materials | PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG |

| Filament size | 1,75mm (on request 2,85mm) |

| Hotend | Double high temperature hotend |

| Nozzle temperature | 500° |

| Print bed temperature | 150° |

| Heated chamber temperature | 140° |

| Electronics | 32-bit |

| Power panic | Automatic print resumption system after a black-out |

| Ethernet connection | WiFi 2,4Ghz |

For all the machines we manufacture, it is possible to develop Custom Automation for the loading and handling of parts, pallet handling, and other customized and unique solutions.

Find how