free demo

Orthopedic milling machine that allows for the easy and fast production of custom-made models for O&P!

Straightforward and Intuitive

Orthopedic milling machine that enables inexperienced operators to use the machine, reducing training costs.

Compact

The compact size, limited weight, and wheels allow the machine to be installed in offices and typically inaccessible environments. With a width of less than 850 mm, it can pass through doors with ease.s.

Flexible

Thanks to OrthoCAM, to the OrthoBLOCK system and to OrthoLIB, it’s possible to realize different models quickly.

Cost-effective

Due to the low purchase, training and maintenance expenses, the production costs are reduced. So this will increase the overall competitiveness of the machine.

A simple processing cycle in just three steps

1 Scan and grinding

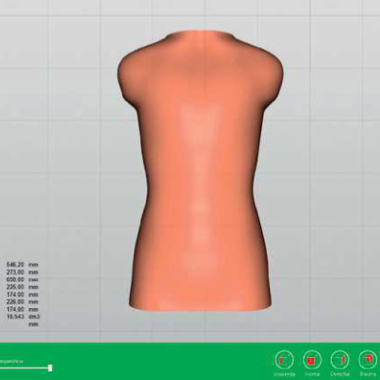

For a quick, precise, and non-invasive acquisition of patient data, various solutions exist, such as the 3D sensor for portable devices. With optional CAD software, it’s possible to import scanned shapes and model them into 3D forms.

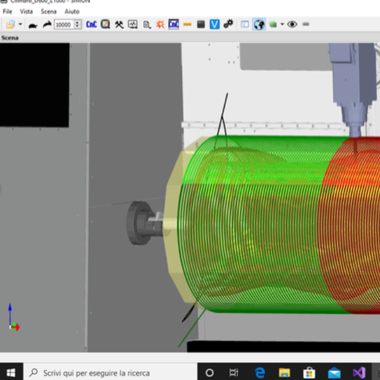

2 Simulation

Thanks to the OrthoCAM software, optional and embeddable in the machine, it’s possible to set up machining quickly and intuitively, without any knowledge of CAM programming.

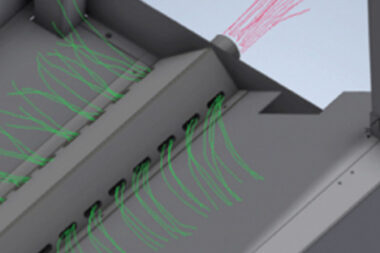

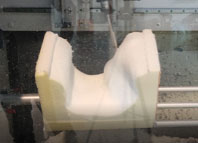

3 Milling

Starting from a block with a maximum diameter of 650 X 1100 mm, that is mounted on OrthoBLOCK, the proprietary quick coupling system designed to facilitate the loading and unloading of the components, it’s possible to obtain the required model with a few simple settings.The collection tank of

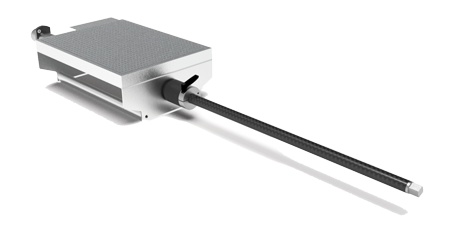

machine, which is connected to an aspiration system, allows to work in an environment free of dust and waste materials.

Do you know that 1000 busts can fit inside your USB drive?

Go digital with SATRES

ORTHO Line's Advantages

Simplified Operator Panel

an intuitive 17” touch screen display

High performarnce Dry processing

of polyurethanes up to 800 kg / m3 wood resin, foam rubber, plastic

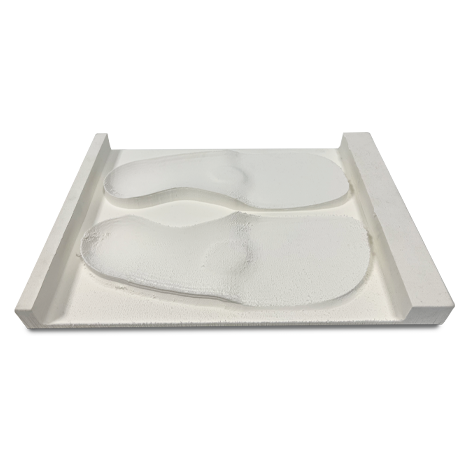

Production of models for prostheses

ready to make prostheses without the aid of plaster casts

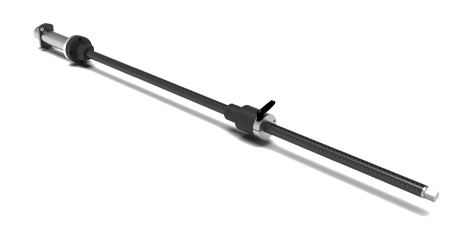

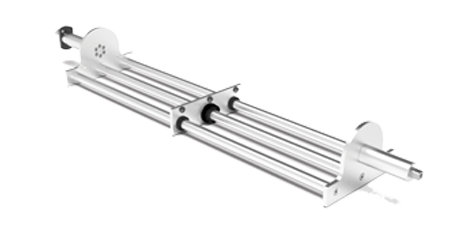

OrthoBLOCK

Proprietary quick coupling system of rotation axis to speed part charge the Procedures (Patent Pending)

Integrated Aspiration System

to keep a clean working area

Ease of transport

Thanks to low weight and wheels, it’s possible install the machine also in office areas

Videocamera

A real time view inside the machine in order to see the milling process

ORTHODUSTEX

Studied and optimized directly to the line ORTHO in order to maximize cleanliness of the cabin

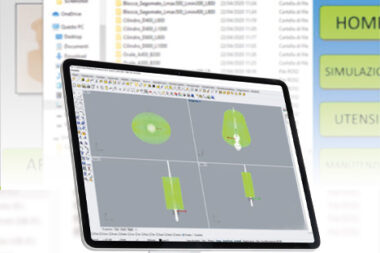

OrthoCAM

for the guided realization of the programs on the machine board, without the aid of external CAMs

OrthoLIB

Pre-set machining library with roughing and finishing parameters

CAM path simulator

and on-board machine collision verification

APP

APP for save the milling programs of the patiens

Do you know that 1000 busts can fit inside your USB drive?

Go digital with SATRES

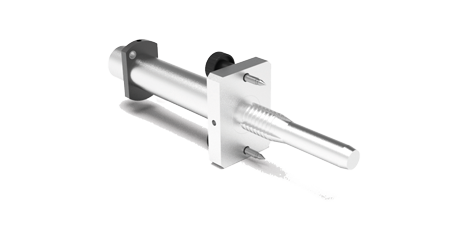

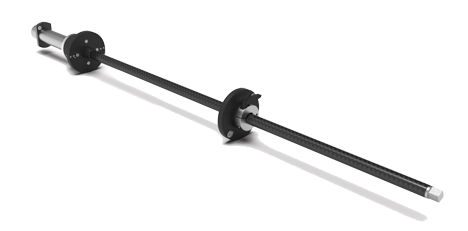

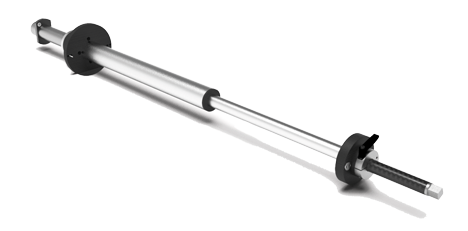

HSM 1003 C ORTHO

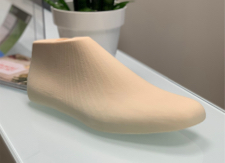

The 3 Axis version allows to easily obtain busts, aesthetic and orthopedic insoles in order to create customized prostheses.

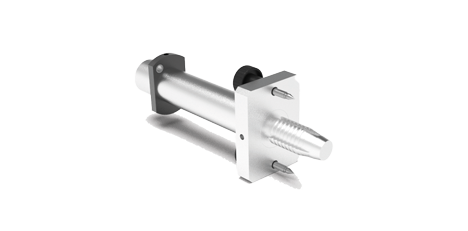

HSM 1004 C ORTHO

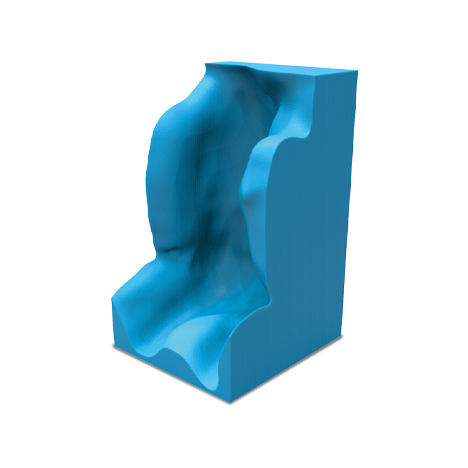

Thanks to 4° axis, it’s possible to add to components’s range to be worked also complex geometries that cannot be made with 3 axis version, such as AFO, KAFO, shape of the shoes and seats.

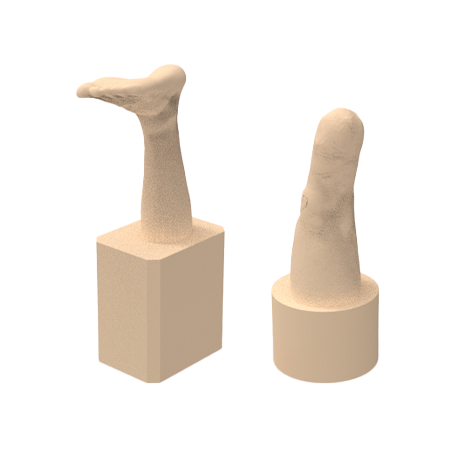

ORTHO’s Applications

ORTHO is the solution designed and created by Satres specifically for the orthopedic sector. Thanks to its 4 axes, the machine is able to produce customized external prostheses and orthoses, eliminating any waste of time.

The production process is organized as follows: after the phases of acquiring and modelling trough CAD software, the prototyping of the designed model takes place by milling. The process starts from a compact block of expanded polyurethane, with a maximum diameter of 600×1000 mm, that is roughed with the appropriate tools. The block is then milled in order to obtain the shape predetermined by the CAD modelling, in a very short time. Thanks to the collection tank, which is connected to the aspiration system, it is possible to work in a environment free of dust and waste materials.

Some possible realizations

ORTHO

The machine is equipped with a numerical control made specifically for orthopedic technicians. The interface with the operator is very simple, and does not need specialized operators. The comfortable 17-inch touch screen offers all the information parallel to the production: Programming and simulation. The machine can be interfaced to work in 4.0 industry.

| Working Area | Axis X | 1100 mm |

| Axis Z | 400 mm | |

| Axis C | Continue | |

| Activation | Spindle speed | 18.000 spindle / min (Option 24.000) |

| Spindle power | 3,5 kW (Option 1 kW) | |

| Spindle Line | Spindle taper | Air Spindle |

| Spindle cone | ER 32 manual (Option automatic tighgtening) | |

| Piece | Max dimension | 650 (diameter) X 1100 mm |

| General data | Machine voltage | 380 V (Option 220 V) |

| Total installed power | 6 kW (Option 3kW with spindle with 1kW) | |

| Footprint | 837 mm X 2103 mm | |

| Machine Height | 2018 mm | |

| Machine Weight with base | 700 Kg | |

| Standard accessories | Numerical control | ISAC |

| Collection’s tank | ||

| OrthoBLOCK Proprietary quick coupling system | ||

| Accessory equipment | Embeddable OrthoCAM and simulator for machine kinematics | |

| Aspiration system | ||

| OrthoLIB Pre-set machining library | ||

| Simplified programming procedure |

||

For all our machines, it’s possible to develop Customized Automation for the part loading and handling part, pallet handling and other customized and unique solutions.

Find how